Summer Material Handling Operations

Summertime…if you follow song lyrics, you know that living is supposed to be easy, but if you work outside or in a bustling material handling facility, it may not be the case. Summer brings elevated temperatures, humidity and vacations, all of which can affect worker performance in any industrial facility, but those working on and around elevated platforms and loading docks can be greatly impacted.

We all know summer feels more loose than other seasons - it’s likely that childhood summer break feeling that we have ingrained into our thoughts. However, that summer feeling should never be applied to safety, especially in material handling applications that feature elevated platforms. Protecting workers at all times - even in the easy months of summer - is a mandate.

While summer doesn’t mean you have to change all of your safety procedures, it’s important to keep a few things in mind.

Hot temperatures and increased humidity can make employees working in operations - especially those outdoors in the dock - tired. When they are tired, they often work more slowly and attention gets focused on how they feel rather than what they are doing. In these conditions, fall protection is of utmost importance. Make sure that employees are using all of the safety equipment correctly, especially when they are working in pallet drop applications on elevated platforms or handling in loading dock operations.

On elevated pallet drop areas, platforms and mezzanines - anywhere an employee works that is elevated inside the facility, dual-gate systems are the right solution. These safety systems use two counterbalanced gates so that when the ledge side gate is down, it provides fall protection for the entire workstation. Employees don’t have to remember to move any equipment back into place when they start picking from the pallet - key when they become overheated.

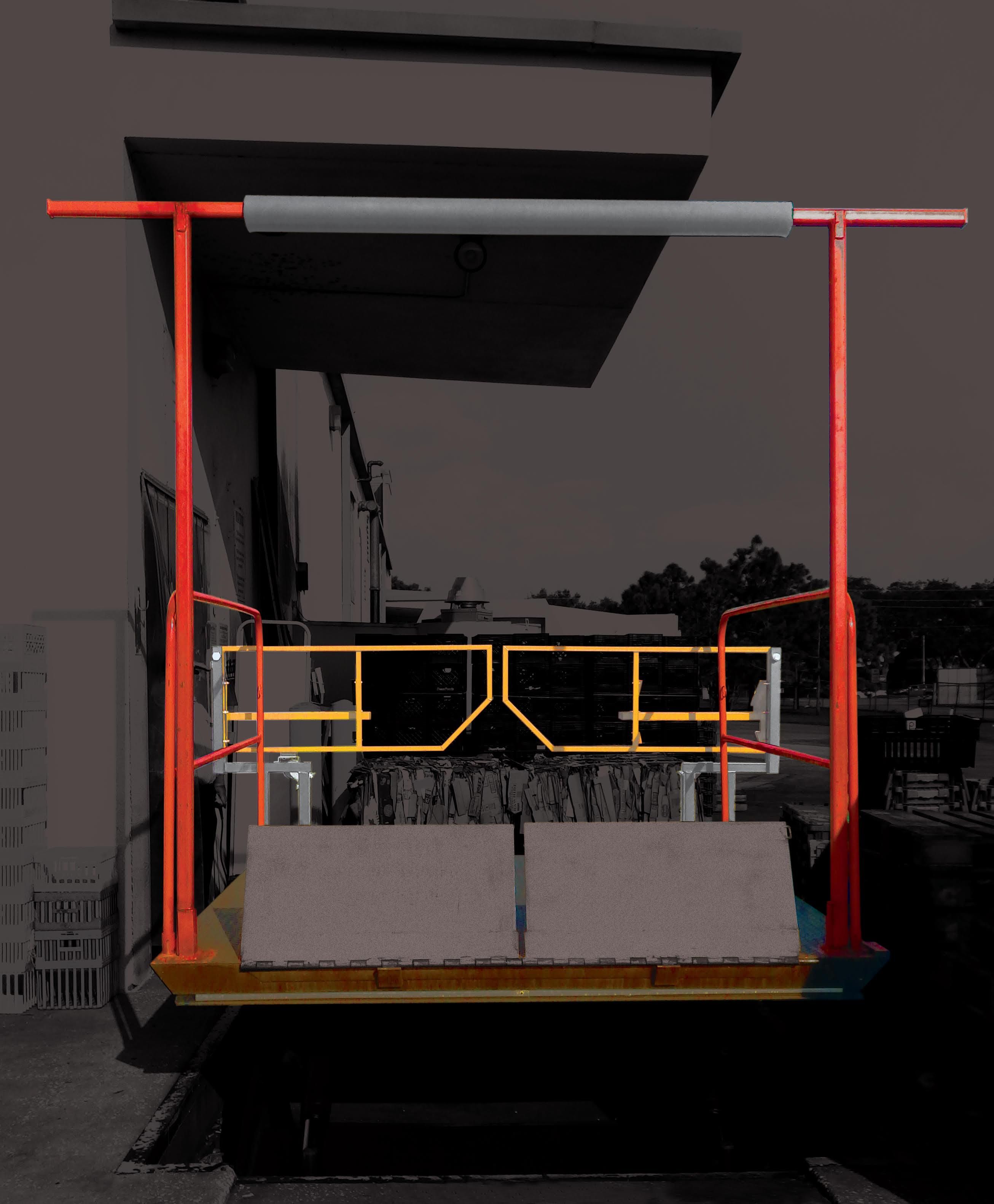

Safety equipment with automated operations, like our Dock-Lift and Loading Dock gate models, provide automatic fall protection; they don’t rely on tired employees to remember to close the gates. In our Dock Lift design, the gates automatically close as the lift begins to rise, and do not open until they reach the dock or ground level. In our Dock Gate design, the gate automatically closes as the truck drives away. Both provide fall protection without relying on workers to remember to close the gates - key to safety in any season.

In addition to temperature extremes, summer brings many vacations - if there are too many employees with time off, temporary workers can be brought in to meet product demand. In addition, if employees have trouble with child care, they may have to bring their child to work - often these “helpers” can be a distraction for all involved in operations.

New employees must understand all safety procedures and know how to run the equipment properly. Take 15-30 minutes each morning to evaluate any new employees - or those that may have “helpers” to determine what training is needed if any, to ensure a safe work environment.

By taking a little time to ensure your operations are safe and that all employees know how to use fall protection equipment, your summer living may be easy after all.